Beginning woodworking

A question I get asked from time to time is how to get into woodworking, what tools I would recommend, and where to start.I can't really make good recommendations as to what specific brands of tools are better than others. Most of my tools were opportunistic purchases, with relatively little regard to specific brands. More often than not, it's price and a quick inspection to gauge the solidity of the tool that are the determining factors. My tools are usually not among the best that can be had, but good enough.

Where to start?

But where to start with woodworking? What machines do you need? My suggestion is that you should start by doing some woodworking, and only after that start buying big equipment.I don't mean that entirely literally. But I think it's best if you buy just a few tools and start using those. As you get more comfortable with what you have, it becomes easier to understand what tools you should get next. It also reduces the risk of buying a workshop full of tools only to find out that you aren't really into woodworking.

Start by getting a few hand tools - a hammer, screwdrivers, nails, a few chisels, a hack saw, a try square, some sort of work table, and some clamps.

Your first power tools should probably be a drill and a jigsaw. Those are tools

that come in handy here and there, even if you are not into woodworking.

You won't be able to make any fine furniture with them,

but it's enough to bang together a few projects for the basement or outside.

Your first power tools should probably be a drill and a jigsaw. Those are tools

that come in handy here and there, even if you are not into woodworking.

You won't be able to make any fine furniture with them,

but it's enough to bang together a few projects for the basement or outside.

There are different grades of tools available at different prices. Salesmen will probably tell you to get good quality tools that last a lifetime. But the price difference between a cheap tool and a good quality tool can easily be a factor of four. My advice is to get cheap tools first and use them until they break. Once they break, it's time to consider getting something better. But unless you are a professional who uses the tools every day, even a cheap tool is likely to last a long time.

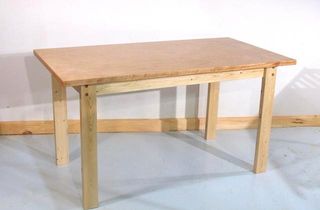

A good tool to get next is some sort of circular saw. A circular saw

cuts a lot faster than a jigsaw, and it's easier to make a straighter cleaner cut

with it. It's also a very useful tool for cutting up big sheets of plywood, even

if you already have a table saw. At this point, you have enough tools for some

simple projects such as this table or some

storage shelving

A good tool to get next is some sort of circular saw. A circular saw

cuts a lot faster than a jigsaw, and it's easier to make a straighter cleaner cut

with it. It's also a very useful tool for cutting up big sheets of plywood, even

if you already have a table saw. At this point, you have enough tools for some

simple projects such as this table or some

storage shelving

You should consider getting a hand plane or two at this point, and maybe a workbench with a vise on it. It may be a good challenge to build a workbench while you are at it.

With just the tools mentioned above, you can already tackle some basic projects, such as these:

Bed from 2x4 lumber |

Simple table |

Storage shelves |

Building sawhorses |

Getting into stationary machines

You can get a lot of hand-held power tools, but after getting the assortment

mentioned above, it's probably time to start looking at getting some

stationary tools.

The most useful stationary tools are a drill press and a table saw. For

the longest time, I only had a cheap old contractor saw, and only a very small drill

press, but I made do with those. The difference between a good drill press

and a cheap drill press is much smaller than the difference between a cheap drill

press and no drill press, so don't wait until you can afford the perfect one.

You can get a lot of hand-held power tools, but after getting the assortment

mentioned above, it's probably time to start looking at getting some

stationary tools.

The most useful stationary tools are a drill press and a table saw. For

the longest time, I only had a cheap old contractor saw, and only a very small drill

press, but I made do with those. The difference between a good drill press

and a cheap drill press is much smaller than the difference between a cheap drill

press and no drill press, so don't wait until you can afford the perfect one.

I can't say the same about a table saw. The cheapest benchtop table saws for under $200 tend to be awful, and will never produce a good clean cut. The better quality benchtop saws are much better, but cost as much as a contractor saw will. A contractor saw is the type of table saw with the motor at the back and open at the bottom. They tend to be made of cast iron, and good value for the money. Hybrid saws are also becoming popular. Hybrid saws are essentially built like contractor saws, but with the motor in the cabinet, just like a cabinetmaker saw. Those are also good value, but much cheaper than cabinetmakers saws. My present table saw is a hybrid table saw. The saw depicted at left is a 40-year old contractor saw, which I enclosed on the bottom to keep the sawdust inside.

To get a cleaner cut, it helps to buy a good quality saw blade for your table saw. With a decent table saw, and a good quality blade, it should be possible to get a cut that is clean enough that it should require only minimal work to prepare it for finishing.

Those tools, plus a bandsaw were all I had when I built my

marble machine one. So you can go quite a ways with just this much equipment.

Those tools, plus a bandsaw were all I had when I built my

marble machine one. So you can go quite a ways with just this much equipment.

A nice thing about a bandsaw is that it's not scary to use. Sure, a bandsaw can cut your fingers off too, but it will probably cut your finger slow enough that you can pull it back before it's a major injury. I cut into my thumb with a bandsaw once when I was a kid. I pulled back as soon as I felt it, and the cut on my thumb wasn't even deep enough to warrant a band-aid. So if table saws scare you, get a bandsaw first.

A bandsaw is also very handy. It cuts cleaner than a jigsaw, but perhaps one of the biggest advantages of a bandsaw is convenience. It's my tool of choice for making most quick rough cuts.I also use it for cutting up long scraps to short pieces to fit them in the scrap box. I really use the bandsaw a lot. I actually bought my bandsaw before I bought a table saw - I saw one marked down at a woodworking show, and I knew I'd get one eventually, so I jumped on it. That was before I built my own

Next it's probably time for some more power tools. A belt sander often comes

in handy. A router is also a really nice thing to have. Don't fret too much

about which router to get - most woodworkers have more than one. So if you don't

like some aspect of your router, it will still be handy as a second router later.

Next it's probably time for some more power tools. A belt sander often comes

in handy. A router is also a really nice thing to have. Don't fret too much

about which router to get - most woodworkers have more than one. So if you don't

like some aspect of your router, it will still be handy as a second router later.

Most people would also recommend that you get some sort of miter saw for making crosscuts. Personally, I have always just used a crosscut sled. Miter saws just don't have the rigidity to produce a cut as clean as can be made with a table saw sled, so I have never been a fan of them.

Moving up to the next level, the next machine to get would be a

jointer planer.

A jointer planer is very important if you want to glue up pieces of wood side-by-side

to make panels. It's just plain all around handy for planing stock. I'd recommend

you get a jointer planer before you get a thickness planer, because there is so much

more that can be done with a jointer than a thickness planer. A thickness planer

is really handy to get stock to the right thickness, although in a pinch, that can also

be done on the table saw by putting the workpiece between the fence and the

blade. If you cut from both sides, you can thikness stock up to twice the maximum

depth of cut of your table saw.

Moving up to the next level, the next machine to get would be a

jointer planer.

A jointer planer is very important if you want to glue up pieces of wood side-by-side

to make panels. It's just plain all around handy for planing stock. I'd recommend

you get a jointer planer before you get a thickness planer, because there is so much

more that can be done with a jointer than a thickness planer. A thickness planer

is really handy to get stock to the right thickness, although in a pinch, that can also

be done on the table saw by putting the workpiece between the fence and the

blade. If you cut from both sides, you can thikness stock up to twice the maximum

depth of cut of your table saw.